Connected Vehicle Data: Boost US Logistics Fleet Efficiency by 10%

Connected vehicle data offers US logistics fleets the opportunity to gain a 10% efficiency increase by optimizing routes, improving vehicle maintenance, enhancing driver behavior, and streamlining supply chain operations, resulting in significant cost savings and improved service delivery.

The US logistics industry is constantly seeking ways to improve efficiency and reduce costs. One promising avenue is connected vehicle data: unlocking 10% efficiency gains in US logistics fleets. This data provides actionable insights that can transform how logistics companies operate.

Understanding Connected Vehicle Data in Logistics

Connected vehicle data refers to the information generated by vehicles equipped with sensors and communication devices. In the logistics context, this data offers a comprehensive view of vehicle performance, driver behavior, and cargo conditions.

This data stream can be leveraged to optimize various aspects of logistics operations, leading to significant efficiency gains and cost reductions.

Types of Connected Vehicle Data

The data collected from connected vehicles can be broadly categorized into several types:

- Vehicle Performance Data: Includes information on fuel consumption, engine diagnostics, tire pressure, and brake performance.

- Driver Behavior Data: Captures metrics like speeding, harsh braking, idle time, and route adherence.

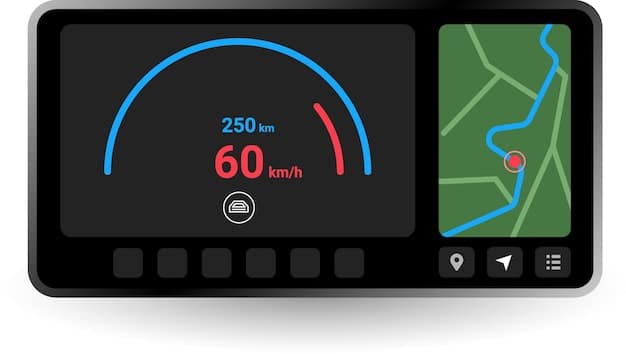

- Location and Route Data: Provides real-time tracking of vehicle location, route taken, and delivery status.

- Cargo Condition Data: Monitors temperature, humidity, and other environmental factors affecting the cargo.

By analyzing these data points, logistics companies can identify areas for improvement and implement targeted strategies.

In conclusion, understanding the different types of data available from connected vehicles is the first step in leveraging this technology for logistics optimization. Each data type offers unique insights that can contribute to a more efficient and cost-effective operation.

Optimizing Routes with Real-Time Data

One of the most immediate benefits of connected vehicle data is the ability to optimize routes in real-time. Traditional route planning often relies on static data and historical traffic patterns.

However, connected vehicle data allows logistics companies to adjust routes dynamically based on current traffic conditions, weather forecasts, and unexpected delays.

Dynamic Route Adjustments

Real-time data enables logistics managers to make informed decisions about route adjustments, minimizing delays and improving delivery times.

This dynamic approach to route planning can lead to significant fuel savings and reduced transportation costs.

- Traffic Congestion Avoidance: Reroute vehicles to avoid areas of heavy traffic congestion.

- Weather-Related Adjustments: Modify routes to account for adverse weather conditions, ensuring driver safety and on-time delivery.

- Unexpected Delay Mitigation: Quickly identify and address unforeseen delays, such as accidents or road closures.

By leveraging real-time data for route optimization, logistics companies can enhance operational efficiency and improve customer satisfaction.

Ultimately, real-time route optimization leverages the power of connected vehicle data to make logistics operations more flexible, responsive, and efficient, reducing both costs and environmental impact.

Improving Vehicle Maintenance and Reducing Downtime

Connected vehicle data can also play a crucial role in improving vehicle maintenance and reducing downtime. By monitoring vehicle performance and identifying potential issues early, logistics companies can prevent costly breakdowns and extend the lifespan of their vehicles.

Predictive maintenance enabled by connected vehicle data can significantly reduce unexpected downtime and maintenance costs.

Predictive Maintenance Strategies

Predictive maintenance involves using data analytics to forecast when a vehicle component is likely to fail. This allows maintenance teams to schedule repairs proactively, minimizing disruption to logistics operations.

Regular monitoring and analysis of vehicle data helps identify potential problems before they escalate, saving time and money.

- Remote Diagnostics: Remotely diagnose vehicle issues, reducing the need for physical inspections.

- Scheduled Maintenance Alerts: Receive alerts when vehicles are due for routine maintenance, ensuring timely servicing.

- Component Failure Prediction: Predict component failures based on historical data and performance patterns.

Improved vehicle maintenance reduces downtime, extends vehicle lifecycles, and decreases overall operational costs, improving efficiency and profitability.

In conclusion, predictive maintenance enables logistics companies to move from reactive to proactive maintenance strategies, enhancing reliability and optimizing resource allocation.

Enhancing Driver Behavior and Safety

Driver behavior is a critical factor in logistics efficiency and safety. Connected vehicle data provides insights into driver performance, allowing logistics companies to identify and address unsafe driving habits.

Monitoring driver behavior can lead to improved safety, reduced fuel consumption, and lower insurance costs.

Monitoring and Coaching Drivers

By monitoring metrics like speeding, harsh braking, and excessive idling, logistics companies can identify drivers who need additional training or coaching.

Data-driven coaching helps improve driving habits, reducing accidents and improving overall safety.

- Speeding Alerts: Receive alerts when drivers exceed speed limits, enabling immediate intervention.

- Harsh Braking Detection: Identify instances of harsh braking, indicating potential safety risks.

- Idle Time Reduction: Monitor and reduce excessive idling, improving fuel efficiency and reducing emissions.

Enhancing driver behavior through data monitoring improves road safety, reduces fuel consumption, and lowers insurance premiums, contributing to more efficient operations.

Ultimately, connected vehicle data enables logistics companies to cultivate a culture of safety and continuous improvement among their drivers, leading to long-term efficiency gains.

Streamlining Supply Chain Operations

Connected vehicle data can significantly streamline supply chain operations by providing real-time visibility into the location and condition of goods in transit. This allows logistics companies to optimize inventory management, reduce the risk of theft or damage, and improve overall supply chain efficiency.

Improved supply chain visibility leads to better inventory management, reduced losses, and enhanced customer satisfaction.

Real-Time Visibility and Tracking

Real-time tracking of vehicles and cargo provides logistics managers with up-to-the-minute information on the status of shipments. This allows them to anticipate and address potential disruptions proactively.

Improved visibility enhances decision-making and enables more efficient supply chain management.

- Real-Time Location Tracking: Track the exact location of vehicles and cargo at all times.

- Condition Monitoring: Monitor temperature, humidity, and other environmental factors affecting cargo.

- Theft and Damage Prevention: Detect and prevent theft or damage to goods in transit.

Streamlining supply chain operations through enhanced visibility improves inventory management, reduces waste, and enhances customer satisfaction, optimizing the entire logistics process.

In conclusion, better supply chain visibility empowers logistics companies to make faster, more informed decisions, ultimately creating a more resilient and responsive supply chain.

Achieving 10% Efficiency Gains: A Case Study

To illustrate the potential of connected vehicle data, consider a case study of a US logistics fleet that implemented a comprehensive connected vehicle program. By leveraging data insights to optimize routes, improve vehicle maintenance, enhance driver behavior, and streamline supply chain operations, the fleet was able to achieve a 10% efficiency gain within one year.

This case study demonstrates the tangible benefits of adopting connected vehicle technology in logistics operations.

Key Success Factors

Several key factors contributed to the fleet’s success:

- Data-Driven Decision-Making: The fleet prioritized data analysis and used insights to inform operational decisions.

- Comprehensive Implementation: The fleet implemented a comprehensive connected vehicle program, addressing all aspects of logistics operations.

- Continuous Improvement: The fleet continuously monitored and refined its strategies, seeking ongoing improvements in efficiency and performance.

The case study highlights the potential for significant efficiency gains through the adoption of connected vehicle technology in logistics operations.

Ultimately, a data-driven approach, comprehensive implementation, and commitment to continuous improvement are essential for unlocking the full potential of connected vehicle data in logistics.

| Key Point | Brief Description |

|---|---|

| 📍 Real-Time Route Optimization | Adjust routes based on current traffic and weather conditions. |

| 🛠️ Predictive Maintenance | Use data to forecast vehicle maintenance needs and reduce downtime. |

| 🚦 Driver Behavior Monitoring | Track driver habits to improve safety and reduce fuel consumption. |

| 📦 Supply Chain Visibility | Get real-time updates on the location and condition of goods. |

FAQ

▼

Connected vehicle data is information generated by vehicles equipped with sensors and communication devices. This data includes vehicle performance, driver behavior, and cargo conditions, providing insights for logistics optimization.

▼

It improves efficiency by optimizing routes in real-time, predicting maintenance needs, enhancing driver behavior, and streamlining supply chain operations. These improvements lead to cost savings and better service delivery.

▼

Data types include vehicle performance data (fuel consumption), driver behavior data (speeding), location and route data (real-time tracking), and cargo condition data (temperature), offering a comprehensive view.

▼

Predictive maintenance forecasts when a component might fail, allowing proactive repairs. This reduces unexpected downtime, extends vehicle lifespans, and optimizes resource allocation, saving time and money.

▼

Monitoring metrics like speeding and harsh braking identifies drivers needing coaching. This improves safety, reduces fuel consumption, and lowers insurance costs, contributing to more efficient and safer operations.

Conclusion

Connected vehicle data represents a significant opportunity for US logistics fleets to unlock new levels of efficiency and cost savings. By embracing this technology and leveraging data insights, logistics companies can optimize their operations, improve customer satisfaction, and gain a competitive edge in today’s rapidly evolving market.