Predictive Maintenance in Transportation: IoT Sensors Reduce Downtime

Predictive maintenance in transportation leverages IoT sensors to analyze real-time data, enabling proactive interventions that can significantly reduce downtime by up to 25%, optimizing efficiency and minimizing operational disruptions.

In the fast-paced world of transportation, every minute of downtime translates to significant financial losses and logistical nightmares. Predictive Maintenance in Transportation: Reducing Downtime by 25% with IoT Sensors is emerging as a game-changing strategy, leveraging the power of data and connectivity to anticipate and prevent equipment failures before they happen.

Understanding Predictive Maintenance in Transportation

Predictive maintenance is not just about fixing things when they break; it’s about predicting when they will break and intervening beforehand. In the context of transportation, this involves using various technologies to monitor the health of vehicles, infrastructure, and equipment.

The ultimate goal? To minimize downtime, reduce maintenance costs, and improve overall operational efficiency.

The Core Principles of Predictive Maintenance

At its heart, predictive maintenance relies on data. Sensors collect real-time information on various parameters, such as:

- Temperature

- Vibration

- Fluid levels

- Operational speed

This data is then analyzed using sophisticated algorithms to identify patterns and anomalies that could indicate impending failures. Predictive maintenance also involves scheduled and unscheduled inspections, as well as the use of a CMMS system to track and manage maintenance activities.

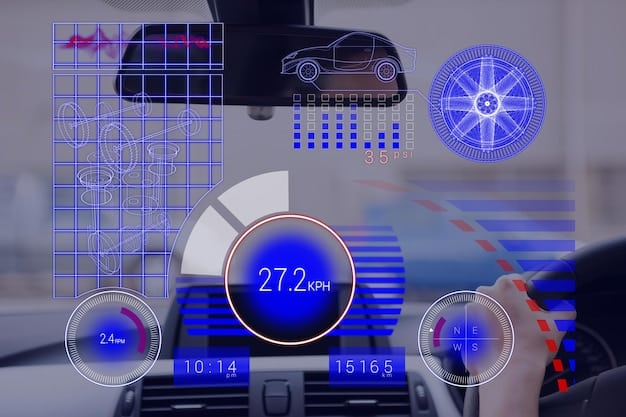

How IoT Sensors Play a Crucial Role

The Internet of Things (IoT) has revolutionized predictive maintenance. IoT sensors are small, inexpensive, and can be easily deployed on virtually any piece of equipment. They provide a constant stream of data that can be used to create a comprehensive picture of asset health.

With the integration of IoT sensors, transportation companies are able to track the performance and condition of vehicles and other assets remotely and in real-time. This constant flow of data makes planning and scheduling maintenance activities easier.

In conclusion, predictive maintenance in transportation is a proactive strategy aimed at preventing equipment failures by leveraging data from IoT sensors. By monitoring critical parameters and analyzing patterns, transportation companies can minimize downtime, reduce costs, and enhance operational efficiency.

Benefits of Predictive Maintenance for Transportation Companies

Implementing predictive maintenance offers a multitude of advantages for transportation companies, impacting everything from cost savings to improved safety.

It’s a strategy that aligns perfectly with the industry’s need for efficiency, reliability, and safety.

Reduced Downtime and Increased Availability

Perhaps the most significant benefit is the reduction in unplanned downtime. By predicting potential failures, maintenance can be scheduled proactively, minimizing disruptions to operations.

This translates to:

- More vehicles on the road

- Increased delivery reliability

- Higher customer satisfaction

Cost Savings Through Efficient Maintenance

Predictive maintenance allows for a more targeted approach to maintenance. Instead of performing routine maintenance on a fixed schedule, maintenance is performed only when it’s needed, preventing the unnecessary repair of healthy parts.

The cost savings stem from:

- Reduced labor costs

- Lower parts inventory

- Less wasted time on unnecessary maintenance, more time on revenue-generating tasks

Enhanced Safety and Reduced Risk

By identifying and addressing potential issues before they lead to failures, predictive maintenance contributes to a safer operating environment. This is particularly critical in the transportation industry.

Benefits include:

- Fewer accidents due to mechanical failures

- Reduced risk of cargo damage

- Improved overall safety record

In summary, predictive maintenance delivers substantial benefits to transportation companies, including reduced downtime, cost savings, and enhanced safety. These advantages make it a strategic investment that can significantly improve the bottom line and overall operational performance.

How IoT Sensors Facilitate Predictive Maintenance

IoT sensors are the backbone of modern predictive maintenance systems. Their ability to collect and transmit real-time data makes it possible to monitor the condition of assets remotely and continuously.

Without IoT sensors, predictive maintenance would be far less effective and far more time-consuming.

Types of IoT Sensors Used in Transportation

A variety of sensors are used in transportation, each designed to monitor specific parameters. Common types include:

- Vibration Sensors: Detect unusual vibrations that could indicate bearing wear, misalignment, or other mechanical issues.

- Temperature Sensors: Monitor the temperature of engines, brakes, and other critical components to identify potential overheating problems.

- Pressure Sensors: Measure fluid and gas pressures to detect leaks, blockages, or other system malfunctions.

- Acoustic Sensors: Listen for unusual noises that could indicate impending failures.

The Data Collection and Analysis Process

The data collected by IoT sensors is transmitted to a central system for analysis. This analysis can be performed using various techniques, including:

- Statistical Analysis: Identifying trends and anomalies in the data.

- Machine Learning: Training algorithms to predict future failures based on historical data.

- Rule-Based Systems: Setting thresholds for various parameters and triggering alerts when these thresholds are exceeded.

This data can then be used to make data-driven decisions, enabling predictive maintenance planning.

In conclusion, IoT sensors play a vital role in enabling predictive maintenance in transportation. By collecting and transmitting real-time data, these sensors provide the information needed to monitor asset health, predict failures, and optimize maintenance schedules. This can all be done remotely.

Implementing Predictive Maintenance: Best Practices

Implementing a successful predictive maintenance program requires careful planning and execution. It’s not simply a matter of installing some sensors and hoping for the best.

Here are some best practices to follow:

Start with a Clear Vision and Objectives

Before embarking on a predictive maintenance initiative, it’s essential to define clear objectives. What are you trying to achieve?

For example:

- Reduce downtime by X%?

- Lower maintenance costs by Y%?

- Improve safety by Z%?

These objectives should be specific, measurable, achievable, relevant, and time-bound (SMART).

Choose the Right Technology and Tools

Selecting the appropriate IoT sensors, data analytics platform, and maintenance management system is crucial. Consider factors such as:

- Reliability

- Accuracy

- Scalability

- Integration capabilities

Train Your Personnel

Predictive maintenance requires a different skill set than traditional maintenance. Technicians need to be trained on how to:

- Install and maintain IoT sensors

- Interpret data

- Use data analytics tools

Additionally, management needs to understand the benefits of predictive maintenance and support the initiative.

In summary, implementing predictive maintenance requires a strategic approach that includes clear objectives, the right technology, and proper training. By following these best practices, transportation companies can maximize the benefits of predictive maintenance and achieve significant improvements in efficiency, cost savings, and safety.

Case Studies: Predictive Maintenance Success Stories

Real-world examples illustrate the power of predictive maintenance in transportation. These case studies demonstrate how companies have successfully implemented predictive maintenance programs and achieved significant results.

Several examples of success can be shown.

Case Study 1: A Trucking Company Reduces Downtime by 30%

A large trucking company implemented a predictive maintenance program using IoT sensors to monitor engine health, tire pressure, and brake performance. As a result:

The company reduced:

- Unplanned downtime by 30%

- Maintenance costs by 15%

- The number of accidents due to mechanical failures

Case Study 2: A Railway Operator Improves On-Time Performance

A railway operator, by monitoring the performance of trains, track infrastructure, and signaling systems, showed that:

The company improved:

- On-time performance by 20%

- Reduced maintenance costs by 10%

- Significantly extended the lifespan of critical assets

These case studies illustrate the tangible benefits of predictive maintenance in transportation. By leveraging IoT sensors and data analytics, companies can achieve substantial improvements in efficiency, cost savings, and safety.

In conclusion, predictive maintenance is a proven strategy for improving performance in the transportation industry. Companies that embrace predictive maintenance can gain a competitive edge, reduce costs, and enhance customer satisfaction.

Challenges and Considerations in Implementing Predictive Maintenance

While the benefits of predictive maintenance are clear, implementing such a program is not without its challenges.

These challenges need to be addressed proactively to ensure a successful implementation.

Data Security and Privacy

The data collected by IoT sensors can be sensitive, including information about vehicle location, driver behavior, and cargo. It’s crucial to implement robust security measures to protect this data from unauthorized access and cyberattacks.

This includes:

- Data encryption

- Access controls

- Regular security audits

Integration with Existing Systems

Integrating predictive maintenance systems with existing IT infrastructure can be complex. It’s important to choose technologies that are compatible with existing systems and to ensure that data can be seamlessly exchanged.

This may require:

- Custom software development

- API integrations

- Data migration

Scalability and Cost

Scaling a predictive maintenance program to cover an entire fleet or network can be expensive. It’s important to carefully consider the costs and benefits of each implementation phase and to prioritize those areas that will deliver the greatest return on investment.

Companies should also consider:

- Cloud computing

- SaaS solutions

- Data analytics platforms

| Key Point | Brief Description |

|---|---|

| ⚙️ Predictive Maintenance | Using data to predict equipment issues and fix them before they cause downtime. |

| 💰 Cost Savings | Reduced labor costs and less need for a large parts inventory. |

| 🛡️ Enhanced Safety | Fewer accidents due to mechanical issues, improving overall safety. |

| 🚦 IoT Sensors | The backbone of predictive maintenance, providing real-time data for accurate monitoring. |

FAQ

▼

Predictive maintenance uses real-time data analysis to anticipate and prevent equipment failures. This proactive approach minimizes downtime and optimizes maintenance schedules, enhancing operational efficiency.

▼

IoT sensors continuously monitor vehicles, infrastructure, and equipment. They collect data on factors like temperature and vibration, providing insights that help predict and prevent potential failures.

▼

Companies reduce labor expenses, parts inventory, and wasted maintenance time. By performing maintenance only when needed, predictive maintenance saves money and prevents unnecessary repairs.

▼

Yes, predictive maintenance significantly improves safety. By identifying and addressing potential issues before failures occur, predictive maintenance minimizes the risk of accidents caused by mechanical faults.

▼

Key technologies include IoT sensors, data analytics platforms, and maintenance management systems. These components gather, analyze, and manage the data needed for effective predictive maintenance.

Conclusion

In conclusion, predictive maintenance in transportation, driven by IoT sensors, presents a transformative opportunity to enhance efficiency, reduce costs, and improve safety. By embracing this data-driven approach, transportation companies can optimize operations, minimize downtime, and gain a competitive edge in an increasingly demanding market.